|

Click on any picture to see a larger version.

The other day I needed to get something off an upper shelf in the shop so I grabbed my Fish Bait Stool

and started to climb up using the stool rungs as a ladder. Not a good idea. A sudden snap and I was on

the floor considering a broken stool and a bruised tush. While I certainly shouldn't have been using the

stool for a ladder, I also saw that the broken rung had been made from a piece of wildly grained wood.

The failure occurred where the gnarly grain ran short across the rung. Clearly, I needed to make a new

rung using straight-grained wood. But how do you insert a new rung without taking apart the whole

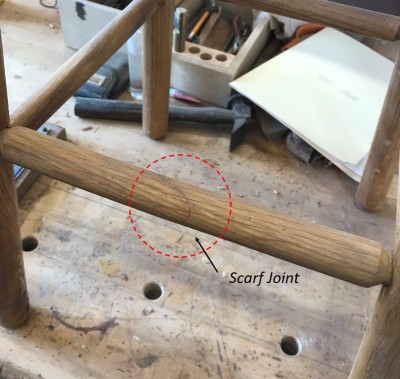

stool? My solution was to turn the replacement and then cut it apart along a sloping scarf. I cleaned out

the broken ends from the holes, glued in the two pieces of the new rung, and then glued the clean scarf

cut back together. Better than new. Grandpa would have been proud.

|

|

A new rung for the Fish Bait Stool, scarfed and glued.

|

My Grandpas knew a lot about how to restore broken things. Grandpa Rummer was the furniture

doctor. He repaired, refinished, and re-upholstered countless pieces that are now cherished heirlooms.

Grandpa Burnham repaired and restored musical instruments, including a violin that its owner

accidentally shot with a handgun. My broken stool led me to reflect on the process of un-breaking

things.

|

|

Figure 2. What to do with a 3-legged table?

|

When we are looking broken-ness in the face, the first step is a decision to fix or not. We compare the cost and difficulty of repairing an item against the cost of getting a new one. In my recent move to Colorado, somehow, I lost one leg from the dining room table. This table is nothing fancy, but it has been in our family for my entire life. It is where everyone gathered at Grandma and Grandpa's for holidays and birthdays. Grandpa had a way to stretch it out to get 15 people around it. It is where we all gathered to share memories and sort out their possessions when they passed. Eventually the table came to me and acquired more scratches and chips that tell of finger painting and puzzles and homework and flaming Christmas puddings. The gnawed off corners on the cabriole legs are the marks of puppies long since gone. In the language of psychology, this table has been imbued with symbolism and deep meaning of "Family".

So, should I fix it or junk it? In its current state I can't even donate it to the thrift store. I would have to make a new cabriole leg (not an impossible task). However, the table is also a bit large for my new dining room and it does have those scratches and wear. Check out this month's poll to vote on what you think I should do. I think we often overestimate the difficulty of repair and we often underestimate the value of the broken thing. I believe restoration is always possible if we are willing to tackle the work.

When we choose to take on the challenge, the first step is to figure out why it broke in the first place. If you put it back exactly the way it was before, odds are it will just break again. I generally look at three factors—stress, design, and material. Many things break when the loads that we put on them (using a stool for a ladder, for example) are greater than what the object can handle. Grandpa fixed a lot of rail-to-chair leg joints. He knew about racking forces and shear forces and how those push chair joints to failure. Don't lean back in your chair, please.

When you understand the stresses that lead to brokenness, consider how the design of the piece tried to resist the loads. Is the joint held together with screws, dowels, mortise and tenon? Did the wood have enough meat (cross-section) to carry the load? Was the joint designed with some bracing members to share the stresses? When you figure out how the joint was supposed to work, you can figure out how to make it stronger when you repair it.

Finally, consider the particular piece of wood that failed. Did it break along the grain or across the grain? Was there a defect in the wood? Is it a weaker species? Bruce Hoadley's book, Understanding Wood, is a great reference to learn more about how wood works (and doesn't!).

With a full diagnosis of the broken-ness, figure out a repair that will make it better than before. Grandpa Burnham was an aeronautical engineer back when airplanes were more wood than metal. His goal was to put wood back together so it could soar again. There are many references on furniture repair techniques but let me briefly highlight a few approaches.

Reglue — Grandpa Rummer was a master at dealing with dowel joints. His minimally-invasive procedure for tightening up wobbly chairs was to inject glue. He would drill a tiny hole into the pocket of the dowel joint and squirt thinned glue through a syringe. If the dowels were too loose or worn it would call for disassembly and cleaning. Get the old glue out because "glue won't stick to glue." New dowels were often needed to fit snugly in the cleaned-out holes. Reassemble and clamp it snug until the glue cures out.

Grandpa Burnham was also an expert with glues. He used a lot of hide glue. There was always that warm, sticky smell in his shop from the glue pot. He emphasized the need to make sure the glue covered the entire joint. No dry spots. He would pry open a crack and work glue into it with a thin palette knife. Then proper clamping — not too tight, just snug enough.

Reinforce — Sometimes the diagnosis calls for adding strength to a joint. There are quite a few chairs that Grandpa Rummer reinforced with metal angle brackets in discrete locations. I found another where he sistered in a piece of plywood on the inside of a cracked chair rail. Splinting across a broken joint with plywood face plates is an accepted repair method for wooden airplanes. Handbooks specify how far the faceplates need to extend on either side of a repair to ensure adequate strength with the reinforcement.

|

|

Figure 3. Grandpa added plywood to reinforce a weak chair rail.

|

Replace — There are situations where the wood is so damaged that a new part is needed. The gunshot violin for example had a section left in splinters by the bullet. Grandpa's solution was to cut out the damage to a clean, solid edge and then fit in a new section of wood. Grandpa Rummer fixed a Jenny Lind bed by making new spindles to match the broken ones. With careful staining and refinishing you can't tell which ones are the replacements.

|

Figure 4. My brother Ken replaced the arm on this rocker,

carefully matching the existing arm.

|

Repair and restoration call for skill and creativity. Many times, the work is more complicated than building a new piece. But the reward of saving a piece, of seeing something come back from a wreck, is especially meaningful. Many of my most cherished heirlooms have a story of restoration.

We live in a throwaway culture. The US Forest Service estimates that 50% of our furniture is discarded before 30 years of use. When something breaks or when we get tired of it, we toss it out and let the trash hauler make it disappear. The internet tells us that we will be so much happier with a shiny new thing that is the style of the season. But those new things have no stories, no connection to ourselves. When the new things first start to show some wear, we are even more likely to dump them in the bin. I think we lose a bit of who we are when we discard things that can whisper in our ear, "We have lived, we have loved, this is who we are."

As for the Fish Bait Stool, I went ahead and reinforced the repair with binding. It doesn't really need the binding for strength, but it reminds me every time I see it that I chose to keep this object. That I invested time and effort into making it whole again. And maybe next time I will be a little more careful about using it as a ladder.

|

|

Figure 5. Proudly testifying to restoration.

|

Bob Rummer lives in Colorado and is a part-time woodworker. He can be reached directly via email at rummersohne@gmail.com. You can see his shop and some of his work at www.JRummerSons.com.

Return to the Wood News Online front page

|