by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 2 of 5)

Previous Page

1

2

3

4

5

Next Page

In A Tight Spot? – Get Skewed!

Despite innumerable distractions throughout the holiday season, work continued to progress (albeit slowly) on the matching pair of natural edge coffee tables. A couple of splits in the slabs required stabilizing and I chose to make and install contrasting bowtie keys (you might call them butterfly or dovetail keys). A video of my process for this has been posted to the Highland Woodworking YouTube site.

Cutting the mortises for bowtie keys is a little different than cutting conventional mortises because the corners of the bowtie are acute angles - something less than a full 90-degrees. Getting a mortise chisel with square sides into that angle to chop out the mortise corners is impossible. Instead, I used a pair of skew chisels, working toward the corner from the inside walls of the mortise. This technique worked perfectly. If you do not have a pair of skew chisels, and many woodworkers do not, you should buy a set for just such tricky cuts. Skew chisels also excel at cleaning up the inside corners of tenon cheek and shoulder intersections and a host of other odd jobs around the shop.

Highland Woodworking sells a pair of Narex skew chisels for just $30. They are a "pair" because one chisel has an angle to the left, the other has the skew angle facing to the right.

|

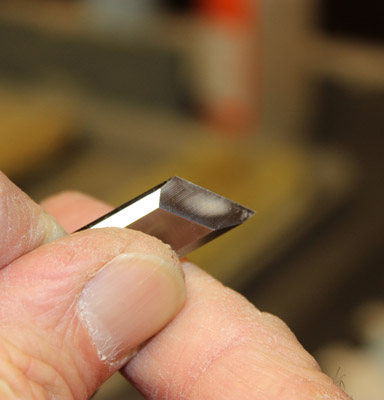

Figure 5 - Click on the photo to enlarge... You

can see the unpolished (dished) section in the

middle of the bevel as sharpening proceeds

|

A lot of manufacturers say their edge tools come sharp, but most do not...at least to my definition of sharp. Forming a cutting edge is actually a three-step process...shape, sharpen, and hone.

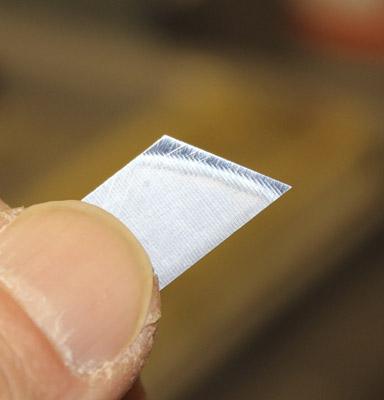

The Narex chisels are shaped, but they are not sharpened. The edges show telltale machining marks indicating a rough grinding to shape. The actual sharpening process is necessary to flatten the bevel, remove the machining marks, begin to polish the edge, and flatten the back of the blade; the honing process will then finalize the polish and put a mirror sheen to the metal.

|

Figure 6 - Look Ma... no jig.

Freehand sharpening is easy, accurate, & faster.

|

I never use a sharpening jig with chisels. It simply takes too long to set up and the results have never been demonstrably better than I can accomplish freehand. Add to that the additional difficulty of mounting a skew chisel in a jig, and it is simply much easier and faster to do it by hand. Place a finger or thumb on the bevel, push it down flush to the stone, rock it slightly to make sure the bevel is flush against the stone surface, let the handle of the chisel rest lightly in your other hand, then push and pull the edge across the stone. A few minutes of practice is all it takes, then you can confidently sharpen any chisel edge without wasting time setting up a jig.

|

Figure 7 - Manufacturing/machining marks start

to disappear as you flatten and polish the back

of the blade.

|

As mentioned previously there is a "right" and "left" bevel chisel in the set. I suppose there is some convention as to which is which, but I have never known...nor do I really care that much. I just instinctively grab the one that I know I need for a particular cut. For the purposes of this description, though, I will refer to one as "right" and one as "left." The "right" skew chisel was somewhat better shaped and easier to sharpen and hone. A dozen or two strokes on the 4000 stone yielded a relatively flat polished surface, ready for honing. The "left" skew chisel, however, was dished on the bevel side of the blade and the back was nowhere near flat. After a few dozen strokes on the 4000 stone it was obvious I needed to go back a step. I went to a 1000 stone, got the blade into better shape, then moved up through the stones. In the end, I wound up with two very keen edges.

The real test, of course, was on the job itself. Making crisp corners in a bowtie mortise involves cutting both with and across the grain, and these chisels performed well on both counts. They also seemed to hold their edge as well as most of my other chisels, even a little better than some. For $30, the pair of Narex skew chisels is a bargain. You will have to do a little work to get the cutting edges in shape, sharp, and honed, but at the price, it is worth a little labor. These are "must-have" special purpose chisels that perform nicely.

(Page 2 of 5)

Previous Page

1

2

3

4

5

Next Page

Return to Wood News front page