by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

This month:

•

A Horizontal Pipe Clamp Rack

•

Random Acts of Woodworking

A Horizontal Pipe Clamp Rack

|

Figure 1 – No way to hang longer pipe clamps

and these were hard to reach.

|

Note: click on any picture to see a larger version.

Through trial, error, and use, tools and accessories that are used most frequently seem to wind

up being closest to hand. Whether you store things on the wall, in a drawer, or on a shelf, the

"stuff" you use most will usually wind up on top or in front. I always thought clamp storage could

benefit from this natural "5S'ing" process (click here for hints on using the "5S" process to organize your

shop).

For years my old clamp racks worked pretty well. But in my new shop, where the pinch cleat had

to be mounted high on the wall, the clamps were hard to reach and due to space restrictions at the

top, I had to hang them from the movable clamp face rather than the screwed-on crank-handle-end of

the clamp. The arrangement seemed a bit insecure.

In my particular situation, I had another problem with vertical wall hanging for clamp storage

--- some of my pipe clamps were simply too long for the space and would hang down over the ledger at

the top of the concrete block portion of the wall and others would hang over electrical outlets.

Horizontal storage seemed like a viable alternative.

|

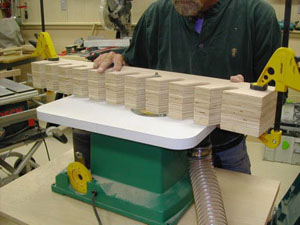

Figure 2 - Horizontal storage proved to be the answer...

more clamps, less wall

space, better arrangement,

easily re-configurable. Build these in a day!

|

I envisioned a number of matching fixtures that could hang from the pinch cleat, be easily

repositioned, and that would have matching notches for horizontal storage of my pipe clamps.

Eventually the clamps I use the most would migrate to the lower storage notches, and the lesser-used

clamps would be at the top.

Having been doing carpentry, plumbing, and electrical work for the past six months, making these

clamp racks seemed like a good way to ease back into woodworking, tune up some tools, and use up

some accumulated scrap material.

From the landing that was built at the turn in my stairs, I had a nice big leftover piece of 1/4"

"cabinet grade" birch-faced plywood. Plywood is excellent for shop fixtures, as it is stable,

strong, and reasonably priced. I also gathered up some scraps of dimensional stock 1 X 4 poplar

that I had used for trimming out windows and doors.

To store pipe clamps horizontally, I needed to figure out how much space would be needed between

clamps. I measured the clamp mechanisms, lined clamps up on the floor, and tried several

configurations. I sketched how the clamp racks might look, and "noodled" out how much support was

needed. When all was said and done, I figured the pipe clamps could rest in notches spaced on

approximately three-inch centers. This might necessitate me having to alternate the direction each

clamp was hung to accommodate the larger crank mechanism at one end, but it would give me the

optimum compromise between space and convenience.

I grabbed a piece of scrap plywood and started to draw a layout. Three-quarter inch black pipe

is one inch in its outside diameter, so I decided to make the slots and resting places for the

clamps 1 1/8" wide. I guessed at a good distance from the edge, drew a line down the board parallel

to that edge, then ticked off a couple of 3-inch on-center locations. Then, using a compass, I drew

in a couple of 1 1/8" circles. I figured I would simply drill out a hole, saw from the edge to the

hole to form a notch, and be done.

At first I drew the lines connecting the circle and the board edge at a 45-degree angle. Looking

at it, this seemed to make the "arms" of the support notches too thin. I changed to a 30-degree

angle, and things looked better --- thank goodness for erasers!

|

|

Figure 3 - At 45 degrees, the support arms were too

skinny and close

together.

|

Figure 4 - At 30 degrees, the support arms were wider

and the space between

them was bigger.

|

When making repeated drawings on a work piece errors can creep in, particularly when drawing

circles. My compass doesn't hold a setting very well. To avoid that, I measured carefully and

marked the holes' center locations, then on the drill press, drilled partial holes at each location

using a 1 1/8" bit. Then, using the partially cut holes, I lined up my bevel angle gauge and drew

lines from the edge of each hole to the edge of the board.

|

Figure 5 - These curves "soften" the points of the support arms

and make it

easier to insert the clamps for storage.

|

I cut some pleasing looking curves into some card stock, and used that to mark out curves on my

template piece where the sharp points of the notches would need to be "eased."

There are a number of different ways to cut out the pipe clamp support arms. The pieces were a

bit long to get into my band saw sideways, but I could use a jigsaw or a scroll saw. I could cut a

template, and then use a router to cut out all the matching parts. Ultimately, I decided to cut one

complete support arm as a template and use a combination of my tablesaw and drill press to rough-cut

all the pieces together. I think this method turned out to be the fastest, and produced the most

consistent results.

|

|

Figure 6 - Saw straight into the edge of the partially

drilled hole. Later,

all the holes can be drilled at once to

assure perfect alignment between support arms.

|

Figure 7 - The template makes aligning the saw blade

easy, and the tablesaw

makes quick work of sawing

five identical pieces.

|

First, I carefully cut out one complete support arm using my Festool jigsaw. I then used the

oscillating drum sander to smooth the lines and add the curve at the pointy end of each cutout.

Double-sided tape was used to securely stack the parts with my "go-by" template on top.

With an auxiliary/sacrificial fence on my miter attachment, and the blade positioned at 30

degrees, I ran the stack through the table saw and cut the longer leg of each cutout. I then

lowered the blade a bit, and cut the shorter leg. If you have a tablesaw sled, use that...it will

definitely be safer.

After the straight portion of each support leg was cut, I moved the stack to my drill press and

used the same 1 1/8" bit to drill the rest of the way through. Go slowly here. Clearing the chips

frequently and allowing the bit to cool a bit will give you less tearout and cleaner holes.

|

|

Figure 8 - Drill all the pieces together to assure alignment

between adjacent

pipe clamp racks. Go slow, clear the

chips frequently and allow the bit too cool.

|

Figure 9 - This could be done by hand, but the oscillating

spindle sander makes

quick work of smoothing and rounding.

|

When everything was cut, I moved back to the oscillating spindle sander and sanded the whole

stack until it matched the template on top.

Make the pinch cleats and standoff pieces next. Set the table saw for a 45 degree cut and move

the fence into position. I use dimensional 1 X 4 hardwood (this time poplar, sometimes I use oak)

nominally 3 ½" wide. I always like to have a small "flat" along the edge of the 45-degree cut so

that the two cleat pieces can fit very snugly together, even if there is some dirt or dust in the

crevice. I used to make a 45-degree rip cut, then slice off a smidgen (a sixteenth of an inch or

so) to produce the flat. By using constant-size dimensional lumber you can eliminate the second cut

by positioning your rip fence so that the 45-degree rip leaves that small flat. Long ago I saved a

scrap to use as a set-up template. I just slide the rip fence over until it matches the scrap and

every pinch cleat in my shop is exactly the same width.

I used a stop block to make sure that all the pinch cleats and standoffs were cut to the exact

same length, in this case, 6-3/4".

|

|

Figure 10 - Stop block assures uniform length cuts.

Note the annoying adhesive

label on this dimensional

lumber is positioned as waste - anyone know a good

way to

remove these things?

|

Figure 11 - Use care to get everything square. Thirty

minutes or so in the

clamps, then turn the units over

and drive the screws from the back.

|

Glue and plywood together do not make a strong butt joint. Unless you are gluing into a dado,

which was way too much pomp for this circumstance, mechanical fasteners are needed to provide the

strength for a hundred or more pounds of black iron pipe and clamp heads. I wanted to make sure

everything was straight and square, so I glued first, clamped everything up square, and let the glue

set for about thirty minutes. I then released the clamps and ran screws in through the back of the

cleat and into the plywood rack through pre-drilled and countersunk holes.

We woodworkers are a frugal bunch and hate to waste wood. The cut-off from ripping pinch cleats

is a perfect little triangle of wood. I have used dozens of these as "stickers" between stacks of

wood, and they work great. This time, I put the little buggers to use as corner braces between the

pinch cleat at the clamp rack support arm – just a little insurance, like wearing a belt and

suspenders!

The standoff at the bottom of each clamp rack exists simply to hold the rack at the same distance

from the wall as the pinch cleat. It does not bear any weight, so I glued those in place and used

23 gauge pins to hold them while the glue dried.

I let everything sit overnight and then gave each unit a light sanding. I didn't bother with

applying a finish as these are strictly utilitarian...but if I had, I probably would have just

applied a coat or two of shellac.

The units can be hung at any distance from one another that accommodates your personal collection

of pipe clamps. I spread mine so that the longest clamps would rest on three supports. Then I

filled in with shorter clamps across two supports. The clamps I use the most are closest to the

bottom, the more infrequently used clamps are on top.

I will soon replicate these, but with narrower and more squared-off notches, to accommodate a

variety of bar clamps (seen hanging vertically in the photo). After a few weeks of use, I really

like the horizontal storage system better than my old vertical storage. One advantage is that the

most-used clamps are closest to the bottom and easiest to access. When all my clamps were hanging

vertically it didn't really matter where each one was located on the rack --- they were all equally

hard to access.

After a couple of weeks I discovered an "unintended consequence" --- actually a benefit --- of

horizontal storage. When you hang a bar clamp vertically, the head ratchets itself all the way to

the bottom by gravity. When I am doing repeated glue ups, I can leave the clamps set in their

respective positions, store them horizontally between assemblies, and they do not move. It may just

be seconds, but it definitely saves time.

(Page 1 of 2)

1

2

Next Page

Return to Wood News front page