by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 4 of 5)

Previous Page

1

2

3

4

5

Next Page

Legendary Sharpening - No Skill Or Effort Required

Click on any picture to see a larger version.

A new friend and regular reader sent an email a few weeks ago asking if I had the Work Sharp, the Tormek, a grinder, or if I used sandpaper or stones to sharpen my tools. As I looked around my shop at the archaeological progression, sometimes regression, and sometimes stagnation of my sharpening efforts, I realized that the sharpening of tools has become an industry within an industry… an industry wrapped in mystique, art, and skill, but with a pervasive dull collective sense that we are all somehow not quite adequate... not quite "fully realized" craftsman...unless our blade edges can split hairs. Sharpening is a source of general frustration for most woodworkers, so I set about looking for a better way.

Over the years I have owned most of the machines that promise keen edges with no work, most of the jigs that promise perfect bevels with no practice, most of the abrasives that promise mirror-polished steel and razor-like sharpness with no fuss, and most of the books that promise to reveal the secrets and methods. I have attended workshops, seminars, demonstrations, and classes. I have cursed, cried, screamed, laughed, and there have even been a few euphoric moments when I thought I finally "got it" only to find out later I didn't. My friend's email struck a nerve.

Oh, we can all sharpen – to some extent. Any reasonable method will yield a reasonably sharp edge. What we all really want to achieve is the perfect molecular alignment of the last 10% of the steel molecules into that perfect juncture between two faces that is so perfect, so sharp, it can split a hair. It is that final 10% that we seek and find so frustrating to achieve. This is where the vast majority of us fail. It is that last 10% that will take us from "merely sharp" to "wickedly sharp" and to which we all aspire. It seems that only when we achieve that level of sharpness will we all be able to take a collective sigh of relief and get back to want we really want to do...work with the wood.

Recently I have been researching the legend and mystery surrounding Damascus steel and swords so sharp that a hair falling on an up-turned blade would purportedly be split in half. All of the scholarly research has focused on the incongruous presence of carbon nanotube filaments and cementite strands in the steel, materials that were unknown, and supposedly unable to be produced, at the time. Finding carbon nanotubes in third-century steel is roughly equivalent to unwrapping a two thousand year old mummy to find him clutching an iPad.

Some metallurgist will someday figure out the mystery of Damascus steel. The steel itself is certainly interesting, but the more intriguing mystery to me is who sharpened that amazing steel to such a fine edge, and how did they do it? How did craftsman achieve a cutting edge of legendary sharpness seventeen hundred years ago?

Today we have diamond-encrusted machine-flattened plates and epoxy-bonded perfectly-sieved and sized abrasives in perfectly shaped sharpening stones. We have jigs that hold our blades at absolute angles and lubricants and polishes that accelerate and smooth the process... yet we cannot toss a silk handkerchief and slice it in half in mid-air using one of our plane blades. But according to historians of the time, one could do that with a Damascus sword. What are we missing? What was the secret our ancient ancestors knew that is now lost to the sands of time?

For the answer, we must turn to history, and to the influence of war and the technological "edge" that often defined winners and losers. We must go back...way back...to the pharaohs of ancient Egypt.

In those days there were very few rules governing human interaction. The only real law was "survival of the fittest," or "conquer or be conquered." Having the sharpest sword or knife was the difference in battles won or lost. And the ancient Egyptians figured out how to achieve that last 10% of perfect sharpness, even with their crude copper and tin blades. Later, as steel-making technology evolved, the secrets of Egyptian sharpening merged with metallurgical innovation, and the legendary swords of Damascus came to be.

The secret, of course, lies in the pyramids. Historians and archeologists speculate that hundreds of thousands of forced laborers struggled with multi-ton stones for decades to build a perfect pyramid simply to bury a king. Hogwash! Nothing could drive that kind of labor expenditure except for an all-out war effort. The pyramids were built to bring "pyramid power" to the sharpening of weapons, so that Egypt could continue to conquer and expand their empire and power. Hundreds of knives and swords were ritually placed in what Egyptologists incorrectly call the "King's Chamber." Actually, this was the main sharpening chamber, and was reserved for only weapons sharpening. The so-called "Queen's Chamber" was a secondary chamber used for sharpening other implements, such as those used in embalming, stone carving, and, of course, woodworking.

|

|

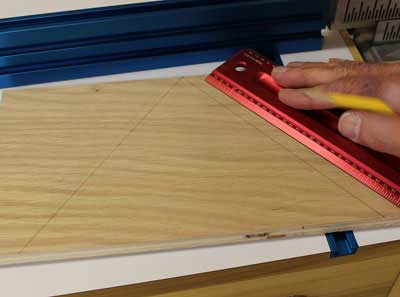

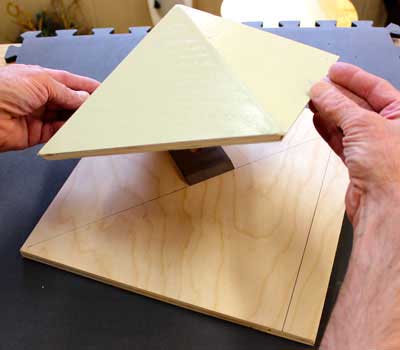

You can easily build your own "Queen's Chamber" for tool sharpening from 1/2" plywood. First, rip two lengths of plywood to exactly 6" in width and at least 22 inches long. Start a half-inch or so from one end and make two marks, exactly 9 7/16" apart, along one side. From those points draw two lines, meeting on the opposite edge of the board at a point dead center between the two marks on the first side. Those should be 38-degree angled lines. Cut just to the outside of those lines, using a 22.5-degree bevel on your miter saw. Make 4 identical pieces and glue the pieces into a pyramid shape. I found that using some 90-degree clamping guides helped hold the assembly together while the glue set up.

If there is a gap or crack, don't sweat it – just fill it with wood putty and move on. It is the base dimension relative to its height that is the key to achieving pure pyramid power. The ratio of the assembled height of the pyramid to the base dimension must be as follows:

Base length ÷ height = pi ÷ 2

Astute observers will note that pi divided by 2 (1.57) is very close to our revered phi, or golden ratio (1.618). Perhaps there is a link? The formula above is provided in case you want to scale up your pyramid. The only advantage to a larger pyramid, though, is the ability to sharpen more than one blade at a time.

While the pyramid glue is drying, cut a square from 1/2" plywood that measures 12" per side. Using a black permanent marking pen, draw a line parallel to one edge of this board 1 – 3/16" inches from the edge. Intersecting that line, draw another line from one corner of the board to the other. This line should diagonally bisect the middle of the board.

Place this board on top of any level surface and, using a compass, align the edge of the board with the parallel line to exactly northwest and southeast (315 degrees to 135 degrees on your digital compass). When positioned properly, the diagonal corner-to-corner line on the board will then run north to south.

|

Take any blade that is sharpened to 90% (this will not work on a blade that is not shaped and sharpened to at least 90% sharpness) and place it on the board so that the edge to be sharpened is lying exactly on top of the north-south (diagonal) line. Place the pyramid over the blade with one side aligned with the northwest-southeast line drawn earlier.

The blade must stay in place, unmoved, through three-fourths of one lunar cycle. I have found it best to place the blade in the "Queen's Chamber" on the "first quarter" lunar date (which will be April 10 this year) and remove it at the "last quarter" date (May 2). This allows the intensity of the sharpening effect to increase gradually through the full moon, then decrease gradually as the moon wanes, not unlike steel heated slowly and cooled slowly will achieve optimal hardness. A nice App called "MoonCalendar" is available for the iPhone and iPad or you can refer to the Farmer's Almanac for moon phase information and dates of upcoming first quarter, full, and last quarter moon phases.

|

I hope now, once and for all, we can all end the quest for the perfect edge and get back to woodworking. Use any method you find pleasing or appealing to achieve "90% sharpness" then use pyramid power to hone the edge that final, heretofore unattainable, 10%. But please, be careful. The edges produced using pyramid power are beyond surgical sharpness and can be quite dangerous.

Oh, and one last very important point...

April Fools!

(Page 4 of 5)

Previous Page

1

2

3

4

5

Next Page

Return to Wood News front page